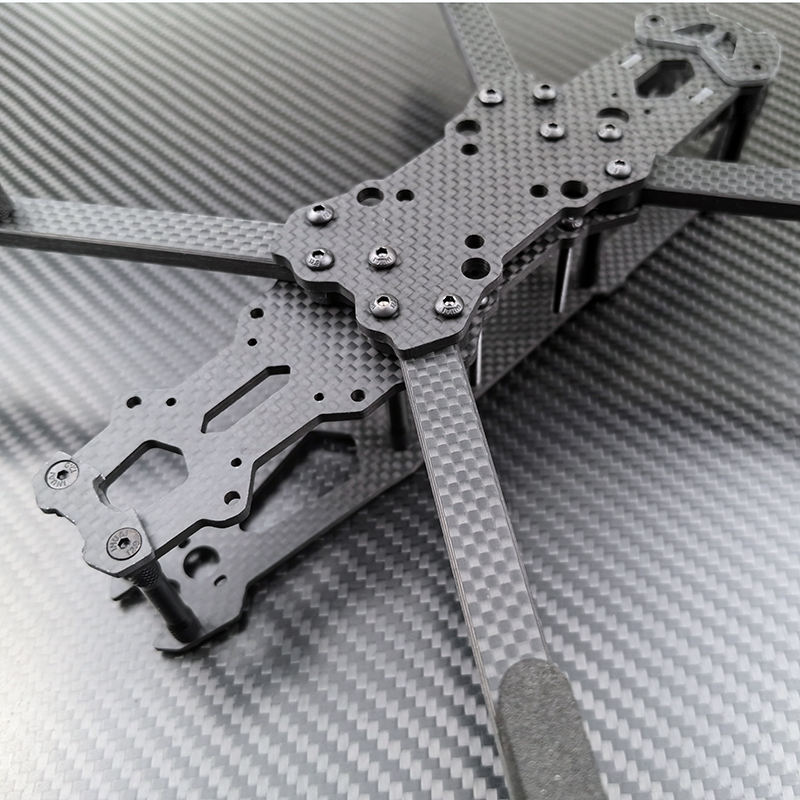

How to cut carbon fiber sheets efficiently and safely

- Sep-03-2025

- (62) Views

Carbon fiber sheet, a basic material, is used in many applications. Sometimes the sizes and shapes provided by sheet manufacturers may not fully meet your requirements.

Therefore, the best way to complete your carbon fiber project is to purchase the sheet and cut it yourself. However, before you begin, there are a few things you need to know to ensure the safest and highest-quality cutting.

1.Safety First

Cutting carbon fiber sheets presents some inherent risks. These include:

Irritation of the skin, eyes, or lungs by fine resin dust particles

Debris

Sharp edges along the cut line

General risks associated with using high-speed cutting tools

Due to the conductive nature of carbon fiber dust, the risk to equipment is relatively big.

To minimize these risks, follow some best practices:

Work in a well-ventilated environment.

Use extraction equipment to remove the generated dust. This can be as simple as purchasing a shop vacuum, or you can invest in equipment such as a downdraft table.

Always wear respiratory protection. Carbon fiber dust is non-toxic, but the fine dust generated by cutting carbon fiber sheets can be irritating to the lungs.

Therefore, it is best to wear a respirator. Use a dust mask rated P1 (for occasional use), P2 (for filtering finer particles), or P3 (for optimal protection). If you are cutting large quantities of carbon fiber sheets, consider investing in a reusable respirator.

Protect your skin. The thin edges of carbon fiber sheets can become very sharp when cutting, so be careful. Additionally, your hands, especially between your fingers, can become very irritated by fine dust particles. Wearing thin surgical gloves can provide protection.

If dust does land on your skin, rinse with water.

Wear eye protection. Whenever working with power tools, it is recommended to wear safety glasses or goggles.

2.Cutting Carbon Fiber Sheets

There are many basic tools that work well for cutting carbon fiber sheets. Here are some options:

Hacksaw: A metal hacksaw equipped with a fine-grit sandpaper blade is ideal for cutting prepreg carbon fiber sheets straight.

Drill: If you need to cut a piece from the inside of a carbon fiber sheet, use an electric drill equipped with a metalworking drill bit to create a pilot hole.

Pole Saw: After drilling the pilot hole, use a pole saw with an appropriate blade to make the cut. Turn on the pole saw, insert the blade through the pilot hole, and screw the saw back together to make the cut.

Angle Grinder: An angle grinder will make quick work of cutting larger jobs. This option is best for making very fast, smooth cuts in straight lines. Because it operates so quickly, errors are more likely to occur, so proceed with caution.

Jig Saw: A jig saw equipped with a tungsten carbide blade is ideal for making curved, shaped, or complex cuts.

3.Polishing and Sanding

After cutting the carbon fiber sheet, you can take a few steps to give the cut edges a final polish:

Purchase or obtain a sanding block to sand the edges. Start by using coarse sandpaper to smooth out any rough edges and debris, then move on to 200-grit sandpaper to smooth the edges.

You can even polish the edges to a sheen with 240- or even 400-grit sandpaper.

To get into detailed areas or corners, use a square, flat, or round metalworking file, depending on the area you're working on.

To get the inside of a cut corner of a carbon fiber sheet really smooth, try rolling up 120-grit wet/dry sandpaper. As with a sanding block, you can use fine-grit sandpaper to create a smooth surface.

In most cases, sanding or filing is all that's needed to create a nice edge on a cut carbon fiber sheet. However, if your product will be exposed to a harsher environment, such as a marine environment, you can mix a two-part epoxy laminating resin to seal the edges.

Look for terms like "epoxy coating resin" on the product label. This coating cures to a clean, hard surface, which can then be wiped with a lint-free cloth to leave the cut carbon fiber sheet with a shiny, smooth, sealed edge.

English

English