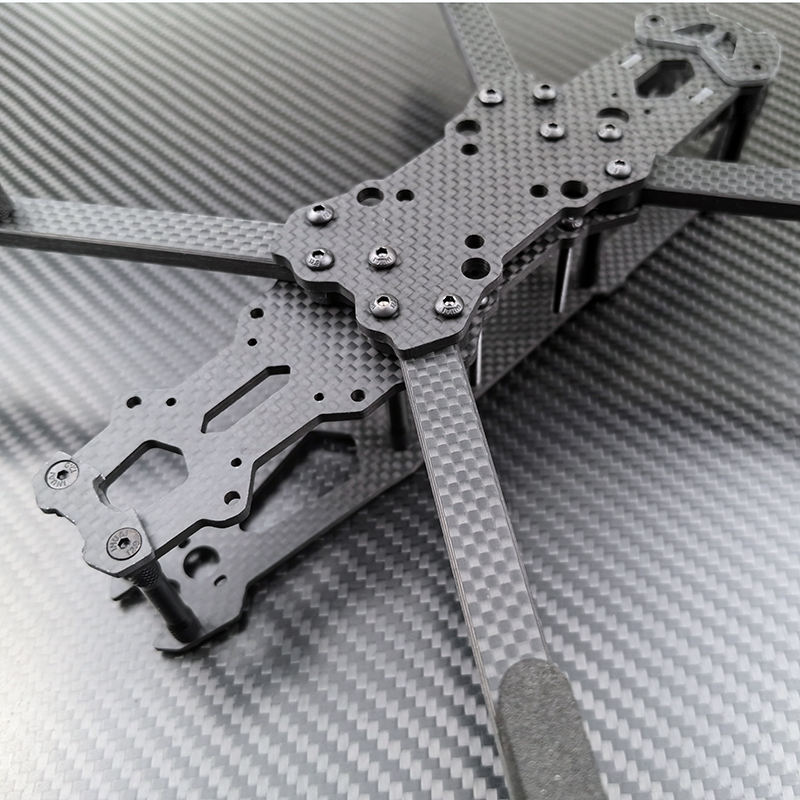

Carbon Fiber Composite Material Compression Molding Process

- Sep-18-2025

- (82) Views

The compression molding process is a process in which a certain amount of prepreg is placed in the mold cavity of a metal mold, and a press with a heat source is used to generate a certain temperature and pressure to heat and soften the prepreg in the mold cavity, flow under pressure, fill the mold cavity, and form and solidify the product.

1.Preparation

Prepare the prepreg, molding tooling, and furnace test pieces, and clean the residual resin and debris in the mold from the last use to keep the mold clean and smooth.

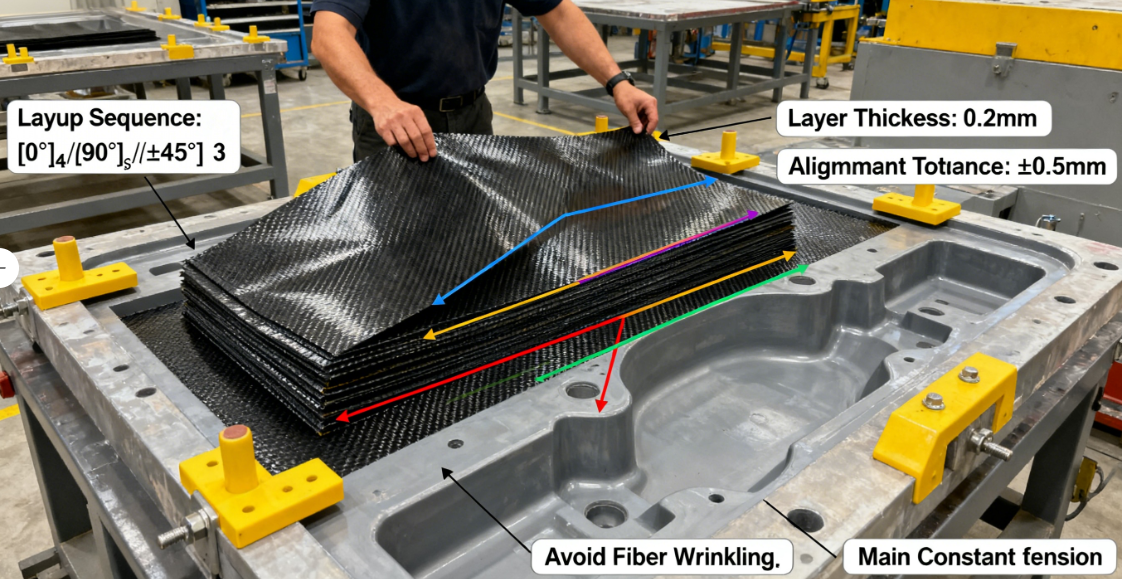

2.Prepreg cutting and laying

Prepare the raw materials of carbon fiber that will be made into products. After the prepreg is re-inspected and qualified, calculate the material area and number of sheets of the raw materials, add the raw materials layer by layer, and pre-press the stacked materials into a dense body with regular shape and certain quality.

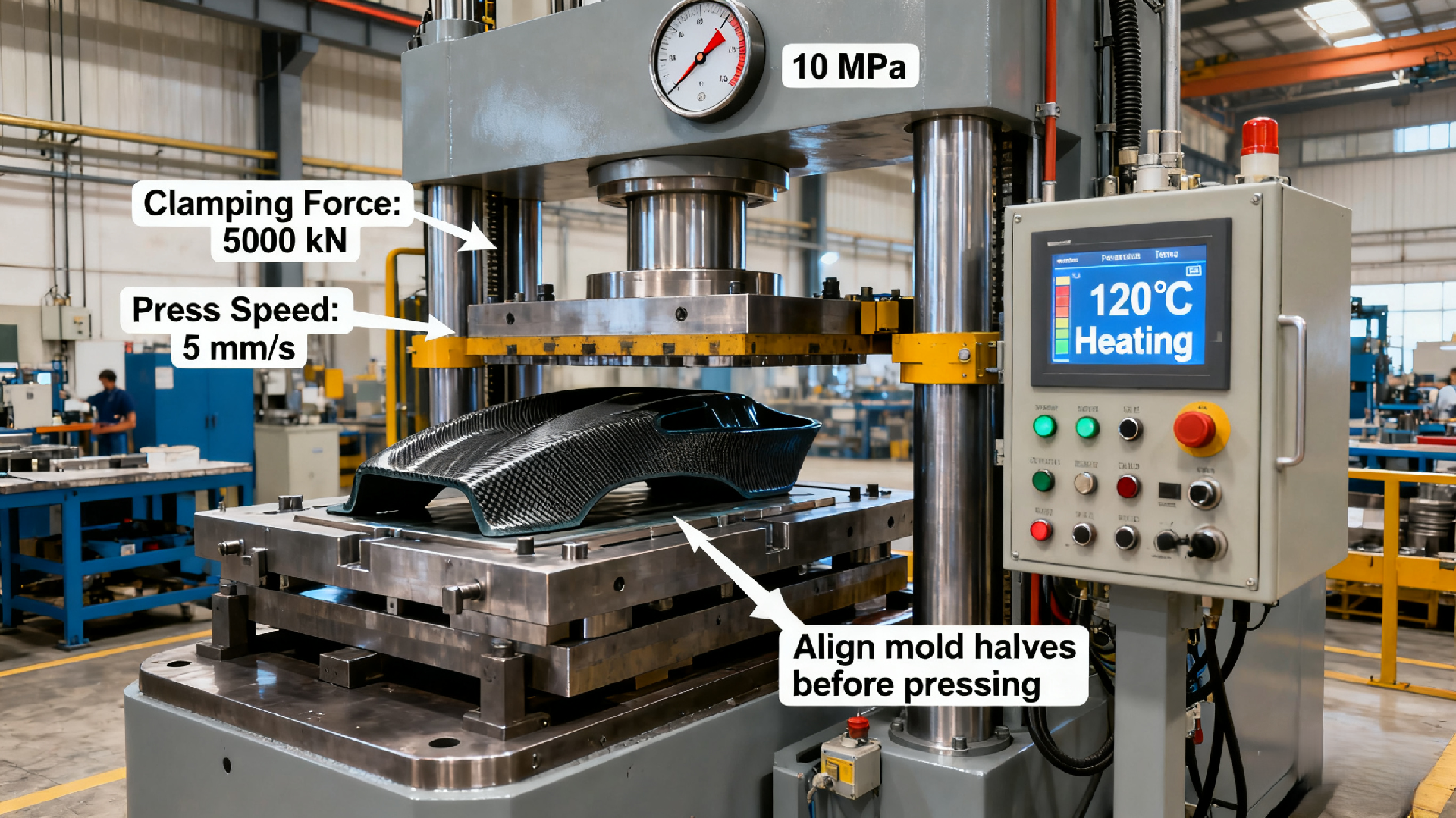

3.Molding and curing

Place the stacked raw materials into the mold, put a plastic airbag inside, close the mold, and put the whole into the mold closing machine. Apply a certain constant pressure and constant temperature to the internal plastic airbag and set a constant time to solidify it.

4.Cooling and demoulding

After the mold has been pressed for a period of time, cool it down for a period of time, then open the mold and perform demoulding and clean the tooling mold.

5.Processing and molding

The product needs to be cleaned after demoulding. Use a steel brush or copper brush to scrape off the remaining plastic and blow it clean with compressed air. Polish the molded product to make the surface smooth and neat.

6.Non-destructive testing and final inspection

Carry out non-destructive testing and final inspection on products according to the requirements of design documents.

English

English