Carbon Filament, Prepreg and Carbon Fiber Cloth

- Oct-10-2025

- (69) Views

What is carbon fiber?

Carbon fiber is a high-strength, high-modulus fiber with a carbon content of over 90%. It is a continuous fiber material composed of stable, continuous carbon molecules in a layered structure. It is made from acrylic and viscose fibers through high-temperature oxidation and carbonization.

1.Carbon fiber specifications

1k, 3k, 6k, 12k and 24k and above large tow carbon fiber cloth, 1k refers to 1000 carbon fiber weaves.

2.Carbon fiber tensile modulus

Tensile modulus refers to the weight per square meter a fiber can withstand before breaking. It reflects a certain level of rigidity and the degree to which a fiber stretches under a certain pressure. The modulus scale is IM6/IM7/IM8; higher numbers indicate a higher modulus and a stiffer material.

Carbon fiber comes in many grades, including high modulus, medium modulus and high strength, and high modulus and high strength. Diameters range from 0.008mm to 0.01mm, with tensile strengths ranging from 1.72GPa to 3.1GPa and moduli from 200GPa to 600GPa.

Higher strength results in greater resistance to pull, while lower strength results in breakage with minimal strain

What is carbon cloth?

Carbon fiber prepreg is a composite material made of reinforcements such as carbon fiber yarn, resin matrix, release paper and other materials through processes such as coating, hot pressing, cooling, laminating, and winding. It is also called carbon fiber prepreg cloth.

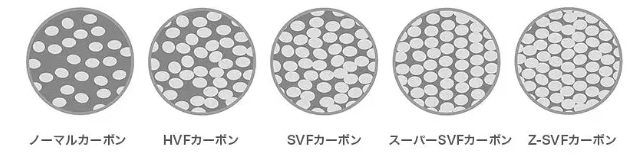

3.Carbon cloth grade

24T-65T (PAN series), low-carbon 24T, 30T, high-carbon 40T, 46T, 60T, 65T, or KCF, KVF, WVF, and VCK. This measurement is based on the force required to stretch the fiber to double its length, indicating its stiffness. For example, stretching 1 cm of 24T carbon cloth to 2 cm requires 24 tons of force.

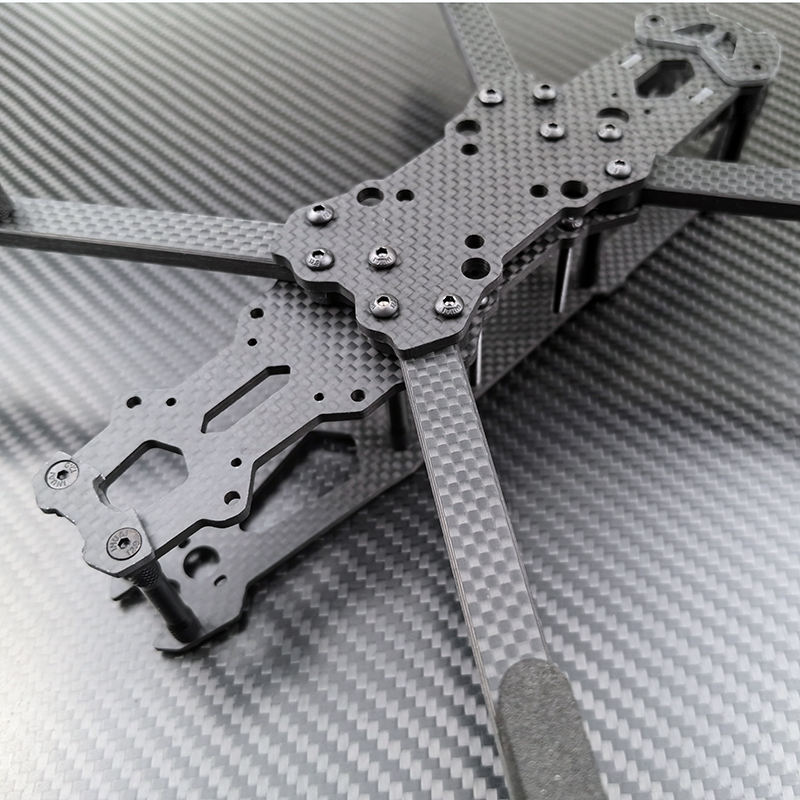

4. Carbon Fabric Types

Each tonnage of carbon fabric is divided into different grades, including epoxy-coated carbon, pure carbon, high-resin low-carbon, and low-resin high-carbon. Quality also varies depending on the carbon filament sorting process and the quality of the carbon sand.

5. Carbon Fabric Weaving Methods

Woven fabrics offer attractive appearance and high interlayer shear stress. However, their disadvantages are low strength and high cost. Most people only recognize carbon fiber by the pattern of the carbon fiber weave; the smaller the k-number, the better looking it is. 1k or 3k carbon fibers are commonly used, but these are not very strong and are expensive.

Unidirectional prepreg offers high strength and stability, allows for customizable lamination angles, and is inexpensive. However, its disadvantage is that it is not recognizable as carbon fiber after molding.

English

English