Types of carbon fiber tubes and common processing methods

- Oct-13-2025

- (121) Views

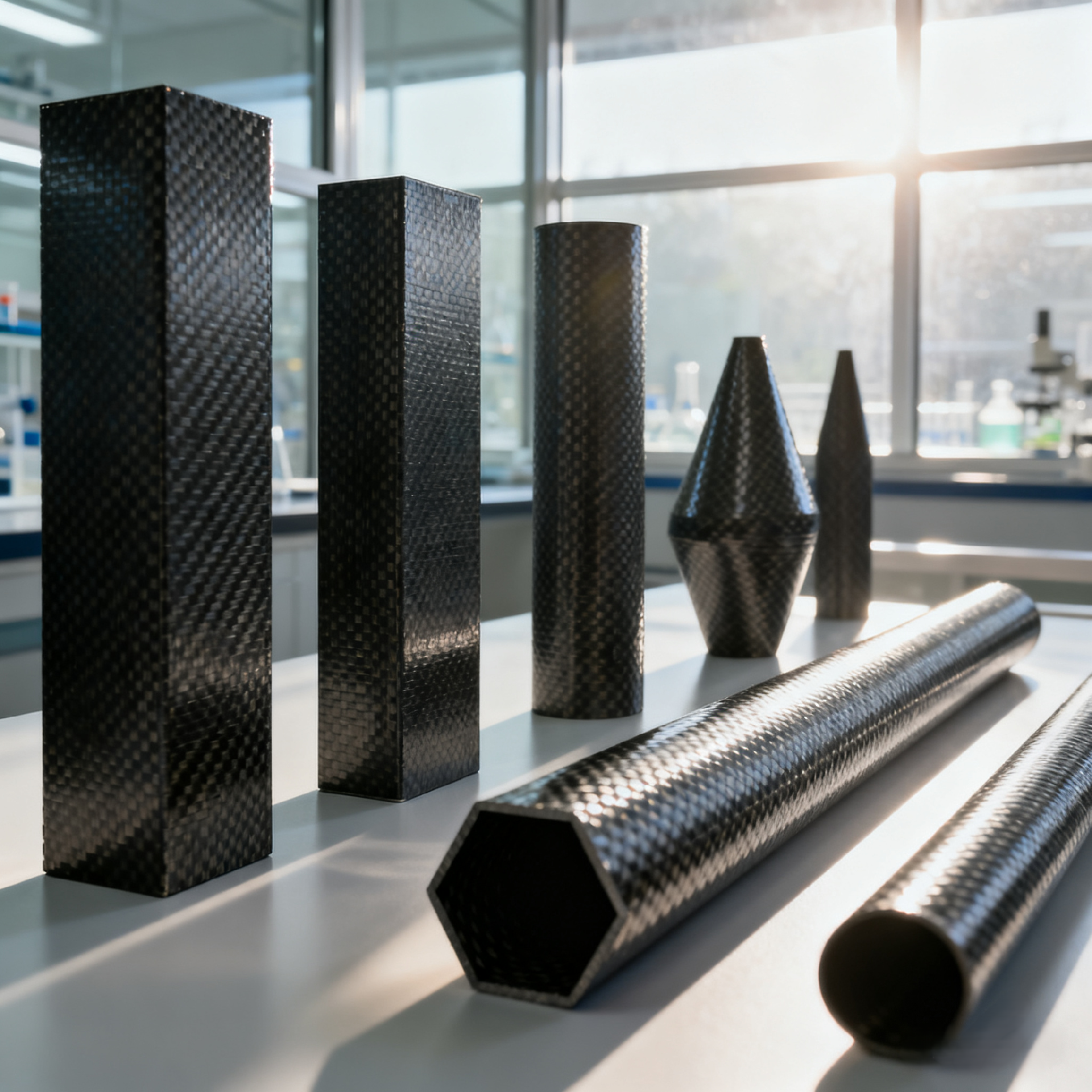

Carbon fiber tubes can be custom-made. Using high-end craftsmanship and state-of-the-art technology, we can produce a variety of tube shapes, including:

Square carbon fiber tubes

Rectangular carbon fiber tubes

Hexagonal carbon fiber tubes

Oval carbon fiber tubes

Tapered carbon fiber tubes (one end has a smaller diameter than the other)

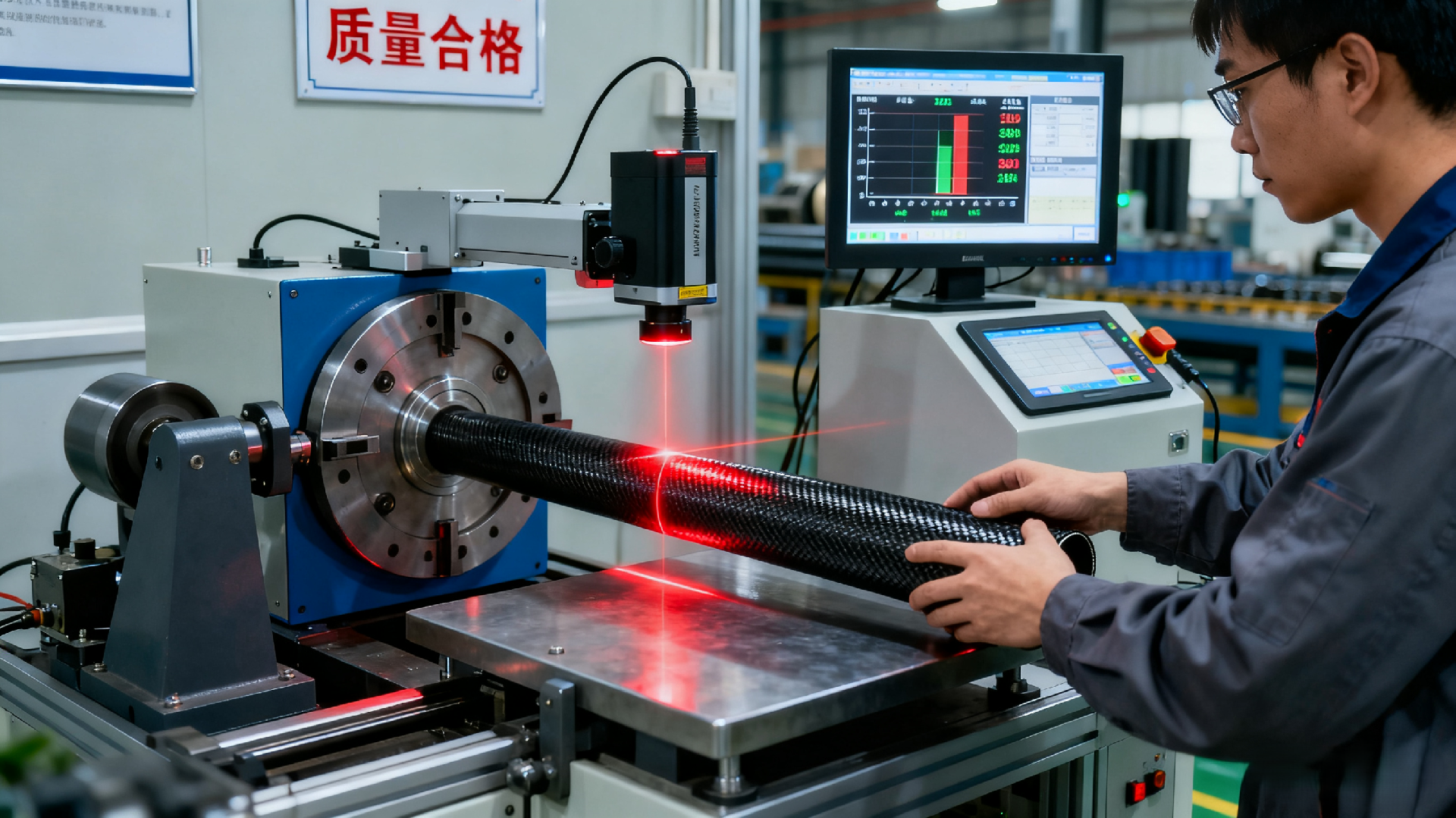

According to the processing method, carbon fiber tubes can be divided into: wound prepreg carbon fiber tubes, braided carbon fiber tubes, pultruded carbon fiber tubes, etc.

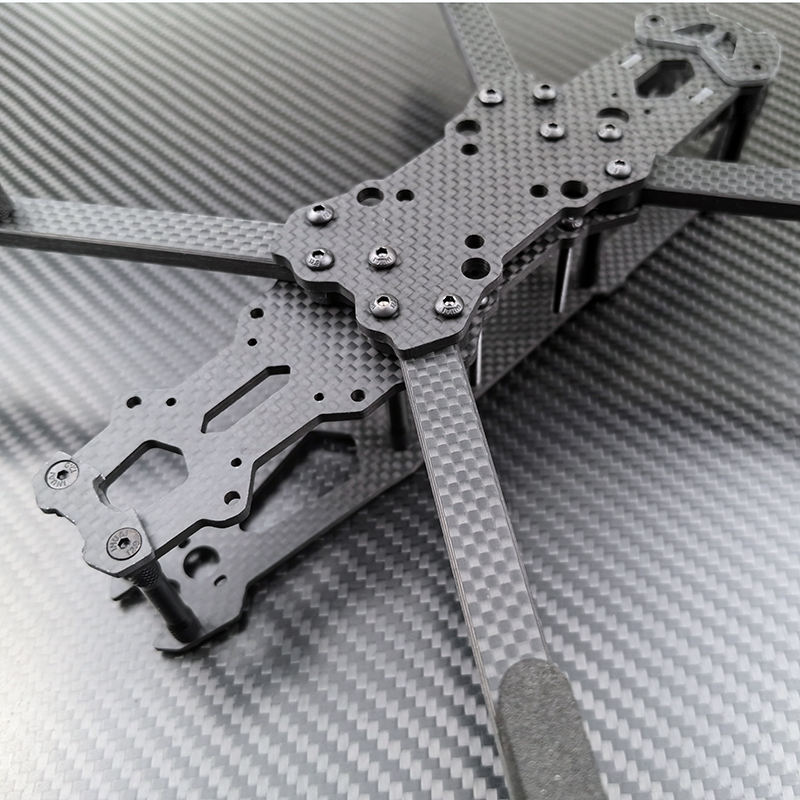

Wound Prepreg Carbon Fiber Tubes: Wound prepreg carbon fiber tubes are manufactured by winding multiple layers of twill or unidirectional carbon fiber prepreg around a metal mold and then curing them at high temperatures. These tubes are ideal for applications requiring maximum flexural stiffness and minimal weight, such as automation, robotics, telescopic poles, and drone components. These long tubes are available with high-modulus and ultra-high-modulus carbon fibers and can also be finished with outer fabrics such as colored Kevlar.

Braided Carbon Fiber Tubes: Braided carbon fiber tubes consist of a carbon fiber braid and unidirectional fabric. They offer excellent torsional properties and compressive strength, making them ideal for high-torque applications. Available in round, rectangular, and square shapes, these tubes can be axially optimized or made with higher modulus carbon fibers for increased bending stiffness.

Pultruded carbon fiber tube: It is made by using carbon fiber (mostly 12k specifications) and epoxy resin/vinyl resin through pultrusion molding process. Pultruded carbon fiber tube has different specifications such as square, round, rectangular, etc.

English

English