Promotion and application of carbon fiber in the drone frame manufacturing industry

- Jun-27-2025

- (116) Views

Carbon fiber composite materials are becoming the first choice for drone manufacturing due to their lightweight, high strength and excellent electromagnetic properties. From the shell to the rotor, it not only reduces weight, but also improves flight efficiency and durability. Advanced processes such as compression molding and autoclave technology further promote breakthroughs in drone performance and help future modular and intelligent development.

As a representative of intelligent aviation equipment, the flight performance and mission efficiency of unmanned aerial vehicles (UAVs) largely depend on the selection of structural materials. Under the requirements of multiple performance indicators such as lightweight, high strength, electromagnetic compatibility, and fatigue resistance, carbon fiber drone shells and drone carbon fiber components are gradually replacing traditional metals and engineering plastics and becoming the mainstream solution.

So, what are the core advantages of drone composite shells? How do lightweight drone parts achieve design breakthroughs through advanced composite technology? This article will comprehensively analyze this flight structure revolution from multiple dimensions of technology, process, performance and market trends.

What is carbon fiber composite material? Why is it the first choice for drone manufacturing?

Carbon fiber composite material (CFRP) is a composite structural material that combines carbon fiber with a resin matrix. It has the advantages of low density (~1.6g/cm³), high specific strength, good thermal stability, and strong corrosion resistance.

Compared with aluminum alloy or engineering plastics, CFRP has significant advantages in impact resistance, fatigue life, electromagnetic performance, etc., and is particularly suitable for aircraft structural design that requires high load bearing and extreme environment adaptation.

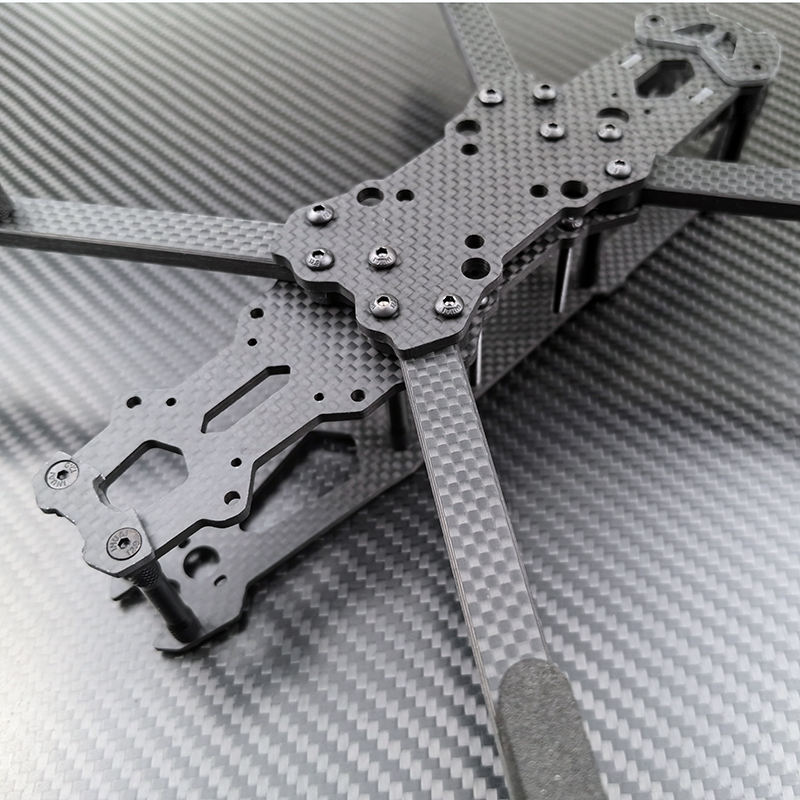

Carbon fiber parts for drones: not only light, but also stronger. The application of carbon fiber in drones has long been beyond the shell, and now covers a variety of parts from structural brackets to functional modules:

Shell and main body: realize the lightweight and high-strength protection of the overall frame of the aircraft.

Rotor and blades: improve aerodynamic efficiency and reduce noise.

Landing gear and mounting bracket: have extremely high pressure resistance and excellent dynamic load bearing capacity.

Communication/radome: have good electromagnetic penetration, suitable for integrated antennas or sensitive electronic equipment.

Especially in high-end reconnaissance and strike UAVs and logistics and transport UAVs, high specific stiffness structural parts have become the core of the design, and carbon fiber components have thus occupied a key position.Carbon fiber composite materials (CFRP) have become the core material for high-end unmanned aerial vehicle (UAV) frame manufacturing due to their excellent properties such as high strength, light weight, corrosion resistance, and fatigue resistance. With the rapid expansion of drones in the consumer, industrial, and military markets, the promotion and application of carbon fiber frames are facing new opportunities and challenges.Consumer drones (such as aerial photography and racing)

1;Requirements: lightweight, high rigidity, and aesthetics (such as the DJI Mavic series).

Carbon fiber applications: arms, center panels, propeller brackets.

2; Industrial drones (such as inspection, logistics, and agriculture)

Requirements: long flight time, wind vibration resistance, and weather resistance (such as XAG agricultural drones).

Carbon fiber applications: integral fuselage frame, impact-resistant landing gear.

3 Military/special drones (such as reconnaissance and target drones)

Requirements: stealth, electromagnetic interference resistance, and adaptability to extreme environments.

Advantages of carbon fiber frame promotion

Advantages | Specific performance |

Lightweight | 50% lighter than aluminum alloy, increasing flight life by 10%-30%. |

High rigidity | flexural modulus 200GPa+, reducing flight jitter. |

Corrosion resistance | Suitable for harsh environments such as ocean and chemical industry. |

Fatigue resistance | No deformation after long-term use, and lifespan far exceeds that of metal. |

Low cost: Non-autoclave processes (such as OOA, Out-of-Autoclave) reduce aviation-grade manufacturing costs.

Intelligent manufacturing: AI optimizes layer design, and digital twins monitor production defects in real time.

Green and sustainable: Thermoplastic carbon fiber recycling technology, bio-based resin application.

Multifunctional integration: Carbon fiber frame embedded with sensors to achieve structural health monitoring (SHM).

The key to promoting carbon fiber in the drone frame manufacturing industry is to balance performance, cost and mass production efficiency. With the maturity of new processes, automation technology and composite material recycling systems, carbon fiber will become the mainstream choice for consumer, industrial and military drones, driving drones to develop in the direction of longer flight time, higher reliability and greater intelligence.

How are lightweight drone parts manufactured? Revealing the core process

Achieving lightweight not only depends on the material itself, but is also inseparable from advanced manufacturing processes. The current mainstream methods for manufacturing carbon fiber parts for drones include:

Compression molding (SMC/BMC): suitable for batch manufacturing of shells and structural panels with complex curved surfaces, with high repeatability.

Autoclave: used for aviation-grade high-performance composite structural parts with high internal density.

Vacuum assisted resin introduction (VARI): suitable for large structural parts, with excellent cost performance.

Prepreg layering + CNC cutting: suitable for small batches of highly customized drone parts development.

Future trends in drone manufacturing: modularization, lightweight, and intelligence

With the emergence of applications such as eVTOL (electric vertical take-off and landing vehicles), unmanned cargo aircraft, and military reconnaissance and strike platforms, the demand for lightweight drone parts with composite structures continues to grow.

Future trends include: automatic layering robots + digitalization

Molding: improve composite molding efficiency and consistency.

Composite materials + embedded sensors: achieve structural status monitoring and intelligent maintenance.

One-piece molding structure design: reduce assembly parts and improve the strength and sealing of the whole machine.

English

English