Why choose carbon fiber medical panels?

- Jan-19-2026

- (39) Views

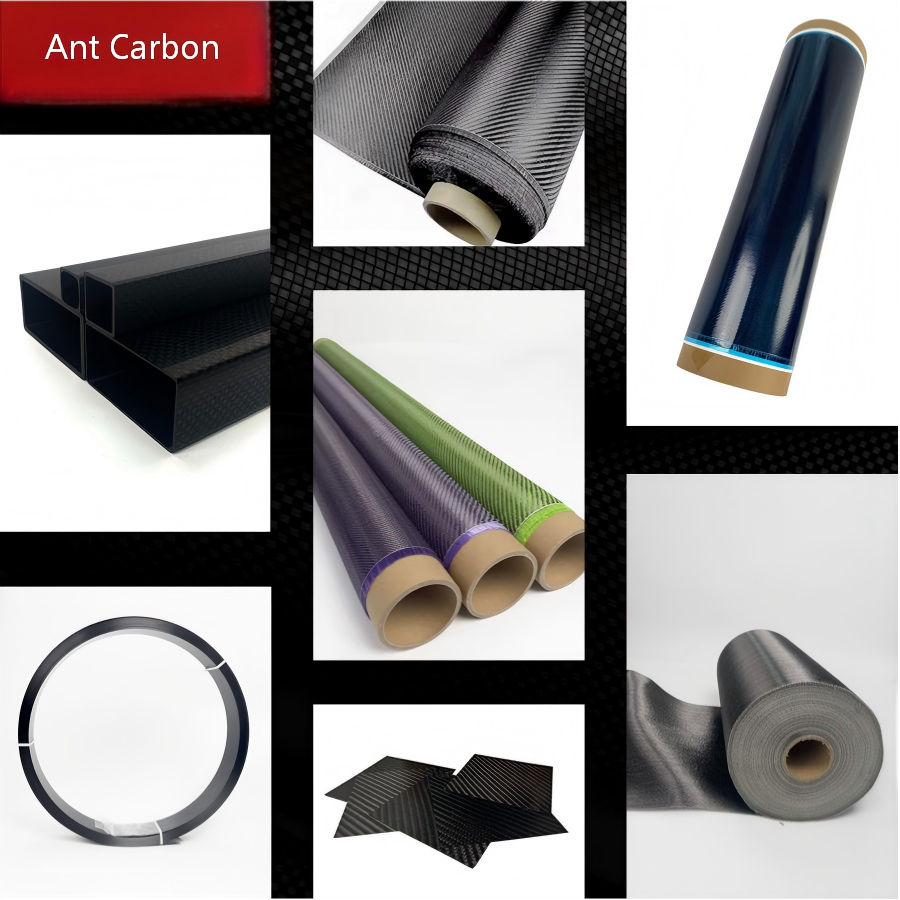

Carbon fiber composite materials are hailed as the king of new materials due to their high strength, low density, and extremely low X-ray absorption rate, and are frequently used to manufacture carbon fiber medical (bed) boards. Carbon fiber medical (bed) boards offer superior X-ray transparency and image clarity, significantly better strength and rigidity than traditional bed boards, good biocompatibility with the human body, and are non-toxic and odorless. They also possess good flame retardancy, heat insulation, and corrosion resistance, playing a crucial role in improving the overall performance of medical equipment.

Carbon fiber composite materials are composed of carbon fibers and resin. Carbon fibers act as the reinforcing material, and the resin serves as the matrix material. In medical applications, the carbon fiber panel acts as the core, serving as the main load-bearing component. Carbon fiber composites have superior specific strength and specific stiffness compared to most structural materials, resulting in outstanding load-bearing performance. When a few fibers break, the load is quickly distributed to the unbroken fibers, preventing damage in a short period of time. Furthermore, carbon fiber also possesses excellent corrosion resistance, capable of withstanding corrosion from alcohol, medications, and blood stains during medical procedures.

The diagnostic accuracy of medical scanning equipment such as X-ray machines and CT scanners is inextricably linked to the X-ray transmission capabilities of the medical board. Medical boards with high X-ray transmission rates can reduce radiation dosage, thereby lowering the radiation harm to both patients and medical personnel; at the same time, they ensure clear imaging and guaranteed diagnostic accuracy. The parameter used to measure the X-ray transmission rate of medical boards is the aluminum equivalent. The smaller the aluminum equivalent, the better the X-ray transmission. The aluminum equivalent of carbon fiber medical boards is only 11% of that of aluminum alloy boards, and even the carbon fiber foam core sandwich panels used as medical bed boards have extremely low aluminum equivalents. All of these factors ensure the high X-ray transmission rate of carbon fiber medical bed boards.

In addition to transmittance and the support strength of the bed board, the service life of medical bed boards also needs to be considered. Carbon fiber is a non-metallic material with low electrochemical activity and excellent corrosion resistance. During diagnosis and treatment, alcohol, medications, blood stains, etc., will not cause any corrosive damage to the carbon fiber medical board, while also meeting sterile medical requirements. Furthermore, it can withstand heavy loads and can be repeatedly subjected to weight-bearing.

In summary, the performance advantages of carbon fiber medical boards are quite significant, and they can play a positive role in improving the overall performance of medical devices. With the development of carbon fiber technology and the stabilization of overall prices, the future application of carbon fiber composite materials in the field of medical devices is immeasurable.

English

English