Learn about the characteristics and applications of carbon fibers ranging from 1k to 48k

- Jan-20-2026

- (43) Views

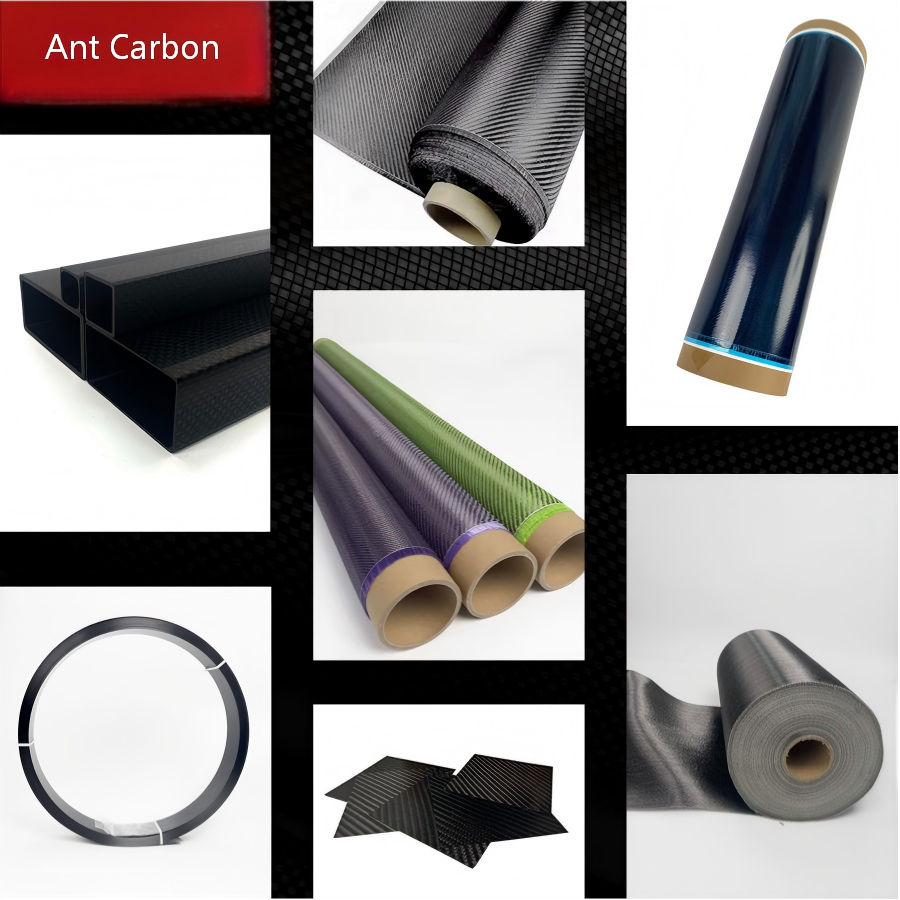

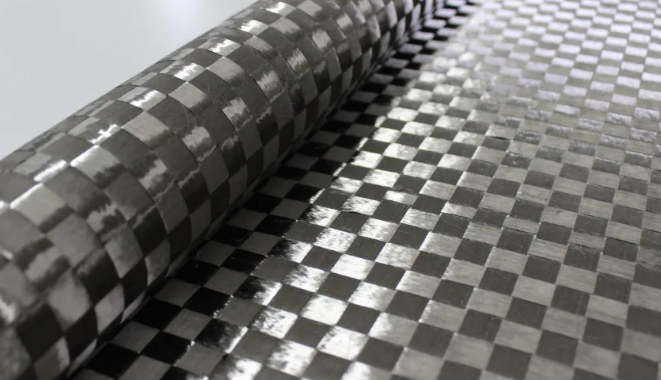

It is well known that carbon fiber is a bundled filament material. Based on the size of the filament bundles, carbon fiber can be divided into small-tow carbon fiber (bundle size ≤ 24K) and large-tow carbon fiber (bundle size > 24K), where K represents one thousand individual filaments in a bundle. For example, 3K carbon fiber means each bundle contains 3,000 individual filaments, while 12K carbon fiber means each bundle contains 12,000 individual filaments.

1. 1K carbon fiber

1K carbon fiber: This is a very rare fiber; it is lighter than other fibers and very expensive. It is mostly used for surface finishing, and most companies cannot even calculate the stress within the weave. Its approximate linear density is 66 grams per 1000 meters.

2. 2K carbon fiber

2K carbon fiber: This is the rarest type of carbon fiber on the market, currently manufactured by no more than two carbon fiber producers worldwide. It provides carbon fiber panels with perfect rigidity, low weight, and good vertical compliance (comfort), but it is also very expensive.

3. 3K carbon fiber

3K carbon fiber: The most popular and common type of carbon fiber. It gives carbon fiber sheets their classic carbon fiber appearance. 3K is the workhorse of carbon fiber, being lightweight, relatively strong, and easy to manufacture. 3K has a higher elongation at break and ultimate tensile strength than 6K, 9K, or 12K.

Due to the smaller tow size of 3K fibers, thinner fabrics can be woven compared to 12K fibers, and they can also be used to wrap thin tubes. They are primarily used in aerospace, industrial, construction, sports, and leisure goods, with a typical linear density of 198 grams per 1000 meters.

4. 6K carbon fiber

6K carbon fiber: 6K is easier to impregnate than 12K and offers better draping properties. It is used in aerospace, structural reinforcement, automotive modification, and other fields, with a linear density of 396 g/1000m.

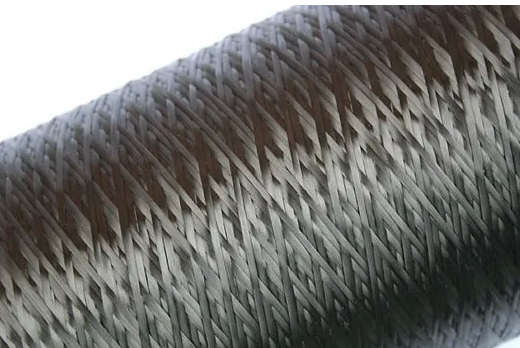

5. 12K carbon fiber

12K Carbon Fiber: Most carbon fiber manufacturers may use 12K to reduce costs, as 12K fabric is cheaper than fabrics with other K counts. 12K is easier and less labor-intensive to produce, and therefore cheaper. It has higher tensile strength but is not suitable for certain bicycle structures. It is mainly used in military applications, industrial robots, and scientific equipment, with a linear density of 800g/1000m.

6. 24K and 48carbon fiber

24K and 48K carbon fibers: These are primarily industrial-grade carbon fibers and are therefore mainly used in the manufacture of filters, insulation, workwear stitching, soft furnishings, and mattresses.

English

English