The difference between 3k, 6k and 12k carbon fiber

- Sep-26-2025

- (398) Views

The "K" here stands for "kilo," referring to the number of individual carbon fiber filaments that make up a carbon fiber tow.

3K means 3,000 individual carbon fiber filaments in a tow.

6K means 6,000 individual carbon fiber filaments in a tow.

12K means 12,000 individual carbon fiber filaments in a tow.

Lower K values produce finer, lighter, and more flexible carbon fiber weaves, while higher K values create thicker, stiffer, and stronger materials. A higher K value generally means:

Relatively lower cost: Producing larger tows is generally more economical than producing smaller ones.

Easier to place and process: Larger tows may be easier to handle in processes like braiding or winding.

The final product may not have a smoother surface than one with a lower K value: Because there are fewer individual fibers, the weave grain may be coarser.

Main Differences

Differences in K numbers directly lead to significant differences in carbon fiber fabric appearance, performance, cost, and processability.

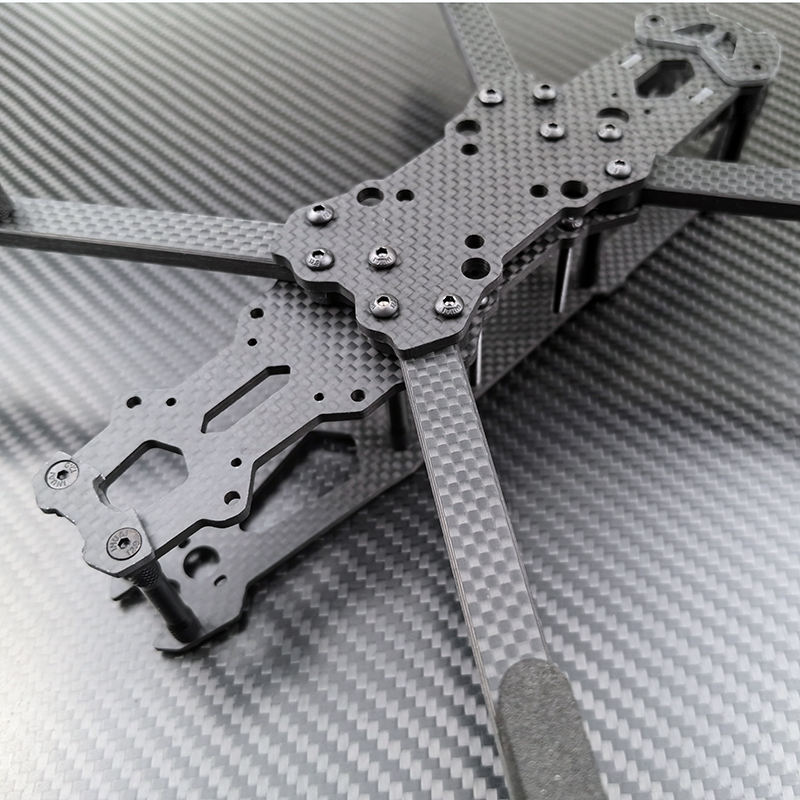

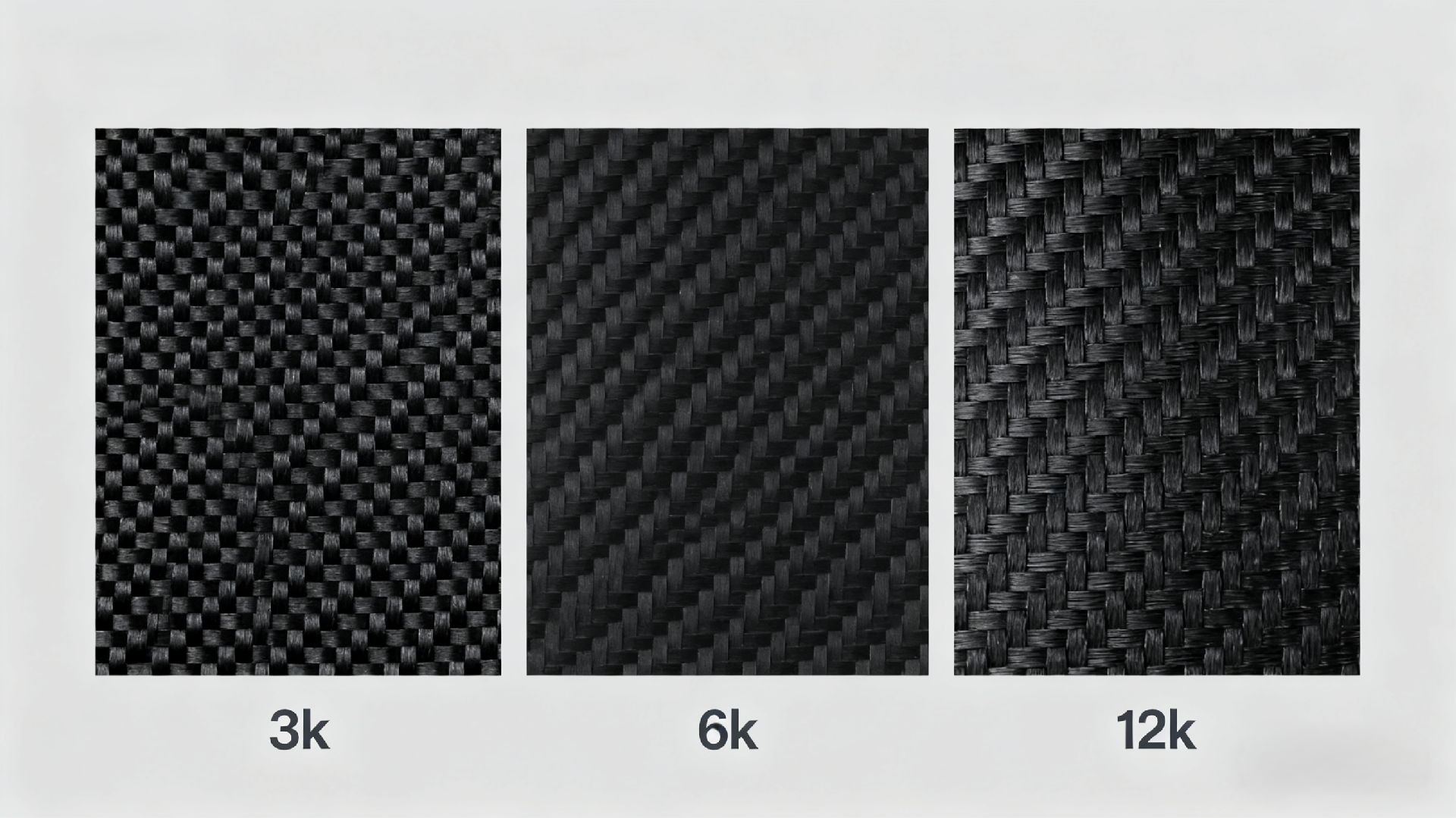

1. Appearance and Texture

3K: The yarns are finer, resulting in a weave with smaller, denser check patterns (such as plain or twill), creating a refined look. This is currently the most common and popular texture for the exterior layer.

12K: The yarns are coarser, resulting in a weave with larger check patterns, creating a rugged, bold appearance. Its distinctive, wide check patterns are clearly visible from a distance.

2. Weight and Thickness

For the same weave, carbon fiber cloth with a higher kilogram count is generally thicker and heavier. Because a 12k tow contains four times the amount of fiber as a 3k tow, the resulting cloth has a higher gsm (grams per square meter). This allows 12k carbon fiber cloth to be more quickly increased in thickness and strength when manufacturing large or thick components.

3. Flexibility & Workability

3K: The fine tows make the resulting fabric thinner, softer, and more drapable. This means it can better conform to complex curves and mold details, resists wrinkling, and is suitable for manufacturing parts with complex shapes and numerous curves.

12K: The coarse tows make the fabric relatively stiff. When working with large curves or sharp angles, 12K fabric struggles to conform perfectly, and can easily cause fiber hang-ups and wrinkles. It also struggles to bend, making it more challenging to work with complex curves. It is better suited for manufacturing large flat surfaces or parts with less curvature.

4. Strength

This is a common misconception. The strength and stiffness of a single carbon fiber filament do not change depending on whether it is bundled into a 3K or 12K tow. The final strength of the product depends on the grade of carbon fiber used (e.g., T300, T700, T1000), the properties of the resin, the layup design, and the manufacturing process.

However, the k-number does indirectly affect performance. For example, thicker 12K tows have a greater crimp angle during weaving, which theoretically may have a slight impact on performance. However, in practice, for most products, the overall structural design, not simply whether the surface layer is 3K or 12K, determines strength.

5. Cost

From a raw material production perspective, carbon fiber with a higher k-number has a lower production cost per unit weight. This is because the process of manufacturing thousands of micron-sized carbon fiber filaments is complex. Bundling more fibers into a single bundle (e.g., 12K) is more efficient and less expensive than separating them into multiple smaller bundles (e.g., four 3K bundles). Therefore, the raw material price of 12K carbon fiber cloth is generally cheaper than 3K.

6. Resin Wetting Ability

The performance of carbon fiber composites depends largely on the degree of bonding between the carbon fibers and the resin.

3K: The finer filaments provide greater penetration space and a shorter penetration path for the resin, allowing the resin to very evenly and completely impregnate each carbon fiber filament. This effectively reduces internal defects such as bubbles and dry spots (areas not wetted by the resin), thereby ensuring the overall performance and stability of the composite.

12K: The thicker center of the filaments presents a challenge for resin impregnation. If the process is not properly controlled, it can easily result in a situation where the exterior is wet but the interior is dry. This can become a weak point in the entire component, significantly affecting its mechanical properties and durability. Therefore, the use of 12K fabrics generally requires more advanced resin infusion processes (such as RTM or vacuum infusion) to ensure high-quality impregnation.

English

English